Metal spraying in SOuthern Africa

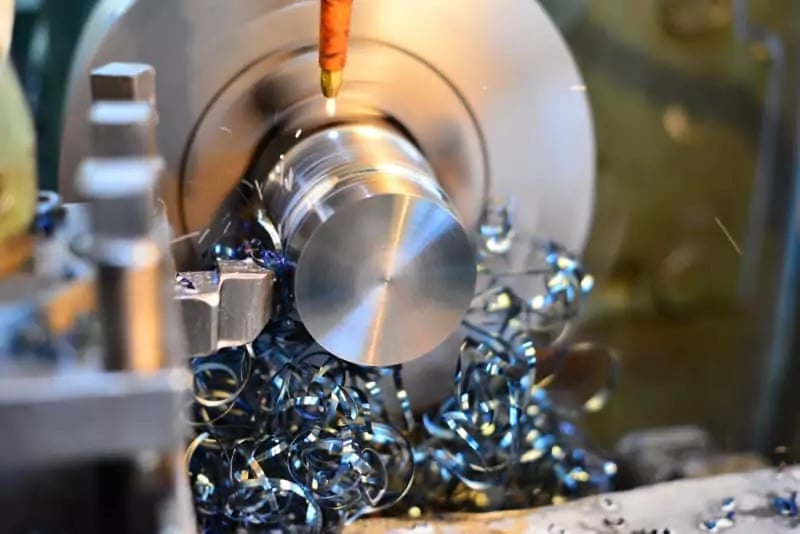

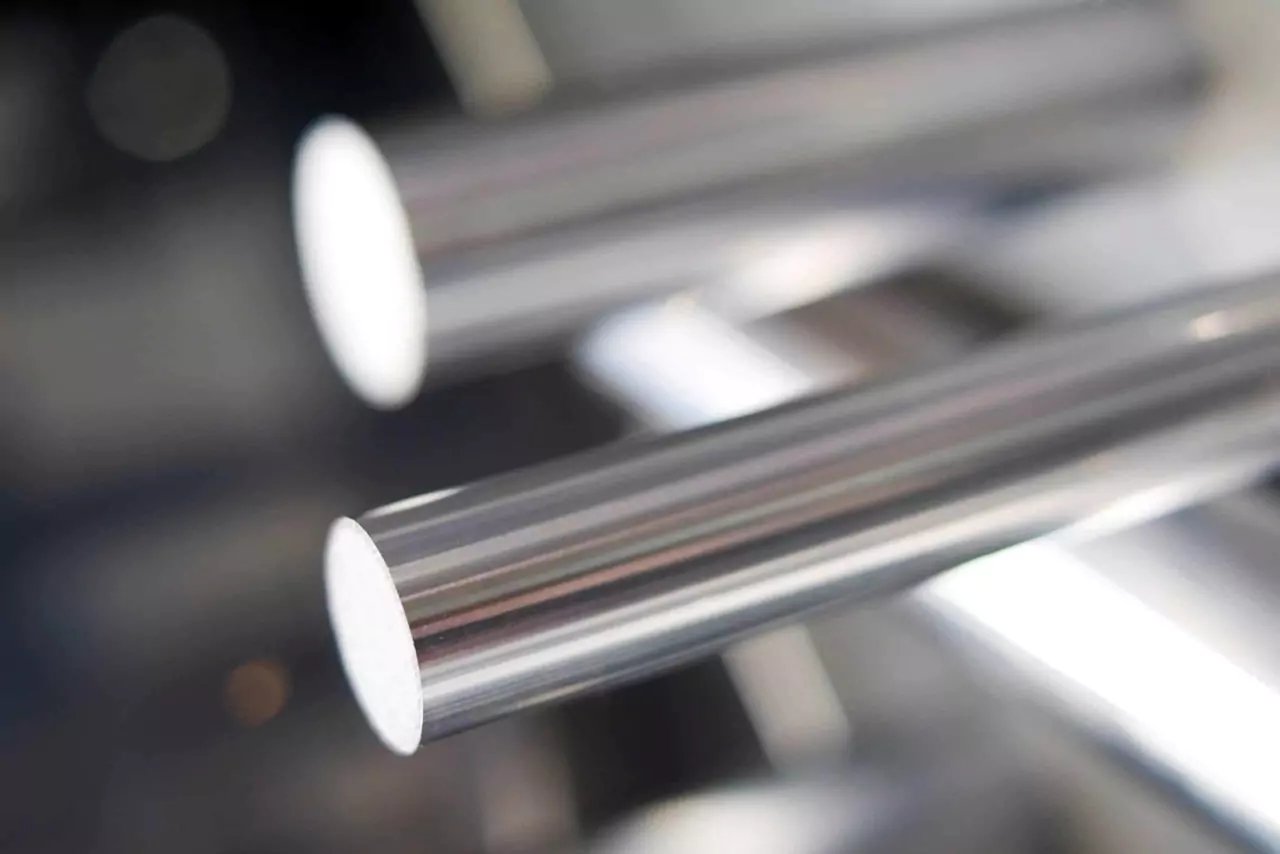

Metal spraying is necessary for anti-corrosion, surface modification or enhancement and for easily rebuilding engineering dimensions. The process is also an alternative to the galvanising process. Honingcraft can offer clients metal spraying services for all hydraulic cylinder needs.

Metal spraying has low heat input, eliminating the risk of component distortion during spraying. This is a big advantage and why the process is popular and cost-efficient.

Surface engineering is an excellent application used on any stainless steel surface. Coating processes increase wear resistance subjecting the source material to a high degree of heat to achieve a molten state. The molten material is then atomised into small particles and sprayed outwards onto a surface.

The molten particles do not heat the surface because the heat of a particle is proportional to its size. On contact, the particle flattens out and adheres to the surface as it hardens. Most applications of metal spraying are in the mining and engineering fields.

Finishing coatings, anti-corrosion layers and thermal barriers add wear resistance. Both flame spraying and arc spraying techniques add protective coatings.

Corrosionpedia chimes in on the methods and advantages of metal spraying below:

“Coatings created by metal spraying range in thickness from 20 µm to several mm, depending on the conditions and method of metal praying used. Deposit efficiency, bond strength, ease of operation, safety, changeover time, maintenance time and costs, the appearance of the coating finish and the ability to automate the coating application affect the choice of spraying method”.

For corrosion protection, aluminium, zinc, and alloys are used.

Subscribe to our newsletter to get expert advice and top insights on engineering and hydraulics.