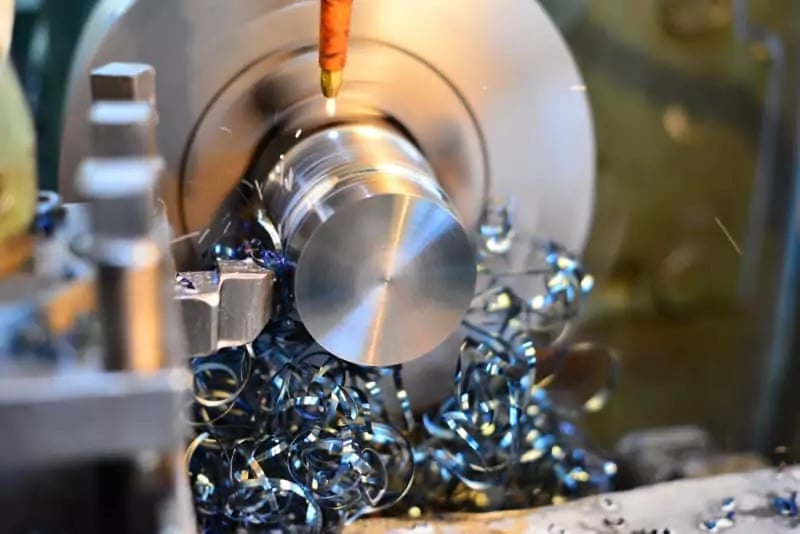

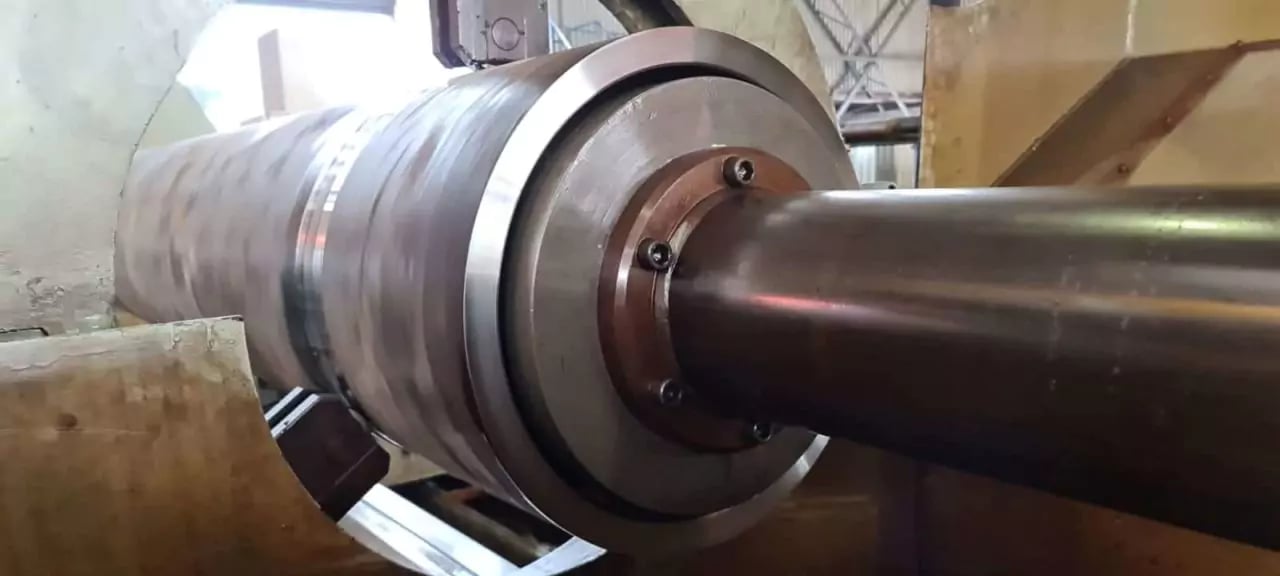

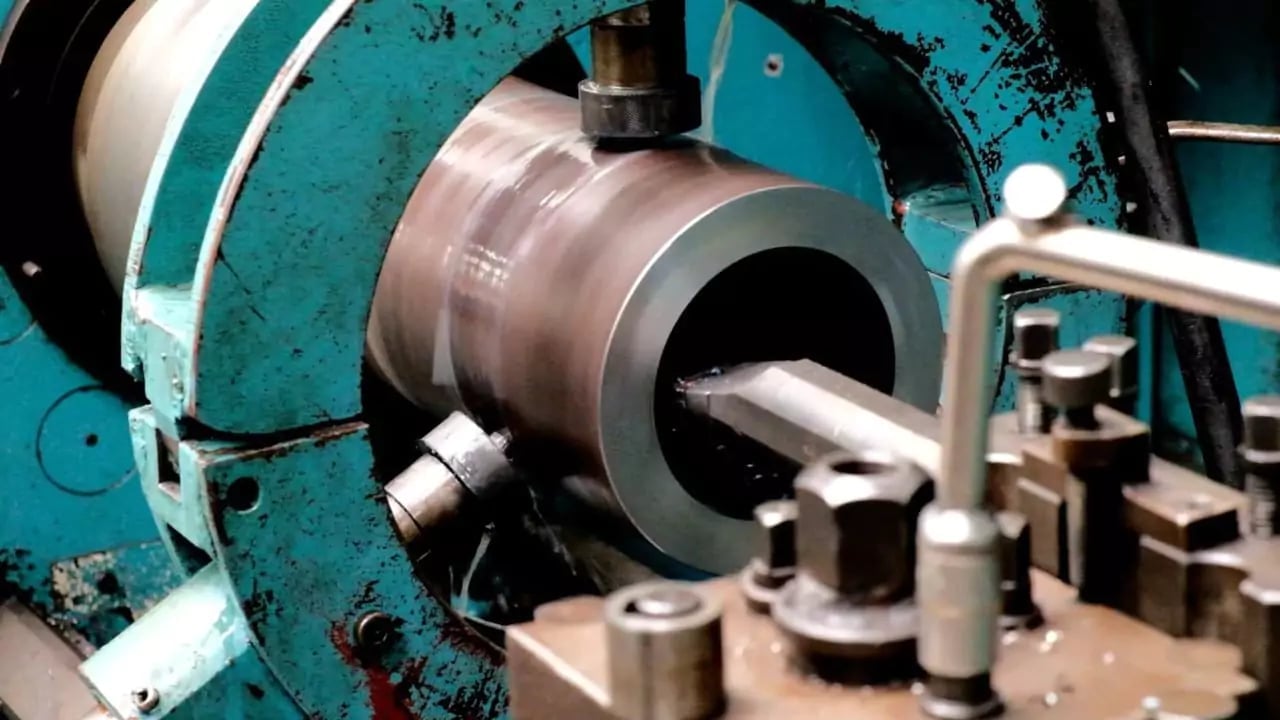

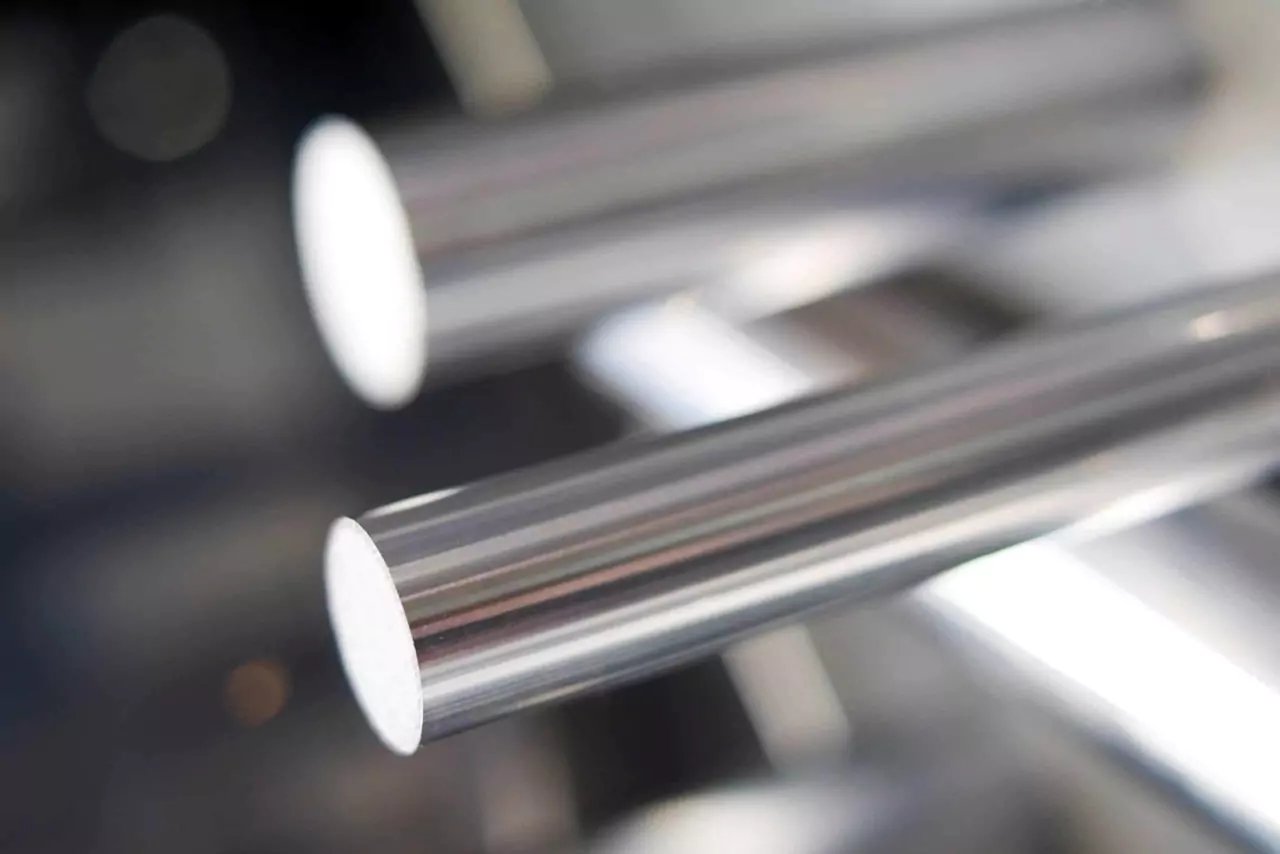

Honingcraft Group Of Companies operates precision grinding machinery to provide surface finishing to exceptionally fine tolerances.

We grind diameters between 30 mm and 1,300 mm in lengths up to 10 metres between centres.

Our grinding equipment is housed in a state-of-the-art facility boasting overhead crane support of 50 tonnes at maximum and a combined 100 tonnes.

Grinding practice is a large and diverse area of manufacturing and toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very hard materials than is “regular” machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to machine such materials as hardened steels.