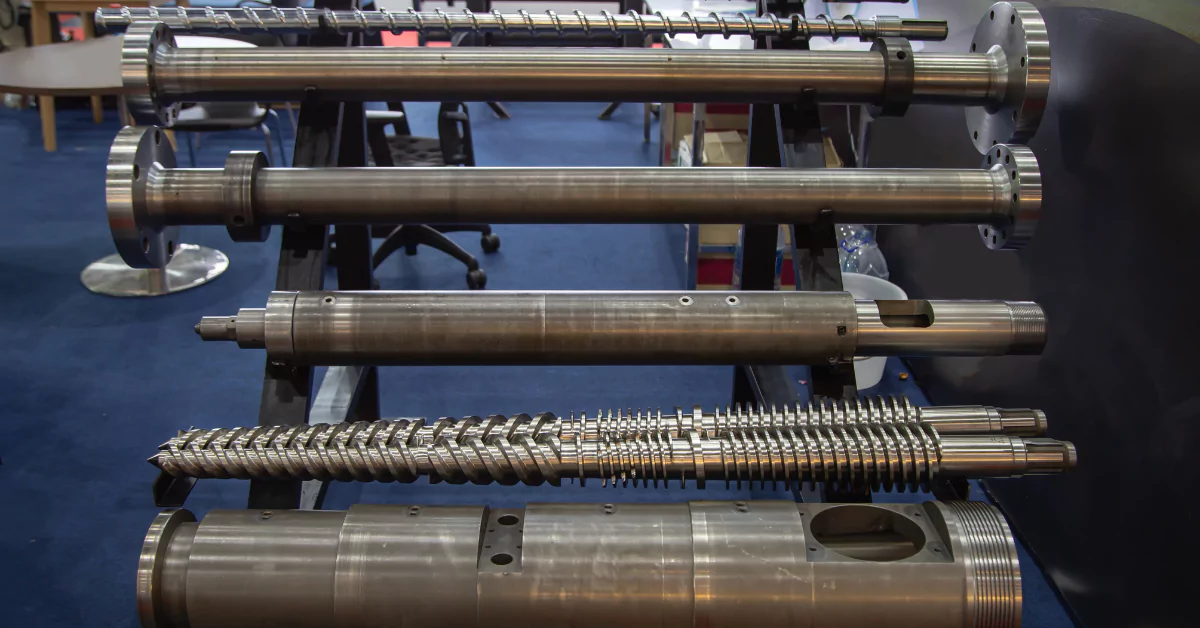

Honingcraft manufactures complete hydraulic cylinder barrels to OEM specifications.

Save up to 25% in time spent manufacturing hydraulic cylinders with complete honed barrels from Honingcraft.

Honingcraft Honed Barrels Process:

- Order a honed barrel from Honingcraft.

- We will source the materials, machine the different components and drill the port holes into the honed tube or hollow bar.

- The different components are then welded onto the tube at Honingcraft.

- The semi-finished hydraulic cylinder barrel is given a final hone.

- Then Honingcraft will package and deliver the honed barrel to your door.

Cut out the hassle and cost of running materials between service providers and cut down on total delivery time by ordering a honed barrel from Honingcraft. This is a particularly great option for our customers outside of South Africa.

Why you should hone your barrels:

Hydraulic cylinder barrels endure conditions of extreme pressure. To make them resistant to the extreme conditions under which they operate, the inside diameter of the barrel is honed to a smooth surface finish, ensuring that the barrel is free from ovality and that the bore is parallel.

The smooth surface protects the piston seals during operation, extending the effective life of the cylinder. The combination of experienced re-conditioners and high-quality machines, ensure that our clients receive the best reconditioned cylinder rods and barrels at an affordable price.

Once you’ve stripped and assessed the damage to a cylinder, determine which part needs to be remanufactured and request a quote. You will cut out the hassle and cost of running materials between service providers and cut down on total delivery time. This is a great option for our customers outside of South Africa.

Hydraulic cylinder barrels endure conditions of extreme pressure. To make them resistant to the extreme conditions under which they operate, the inside diameter of the barrel is honed to a smooth surface finish, ensuring that the barrel is free from ovality and that the bore is parallel.

The smooth surface protects the piston seals during operation, extending the effective life of the cylinder. The combination of experienced re-conditioners and high-quality machines, ensure that our clients receive the best reconditioned cylinder rods and barrels at an affordable price.