Pellet Die Refurbishing Services in South Africa

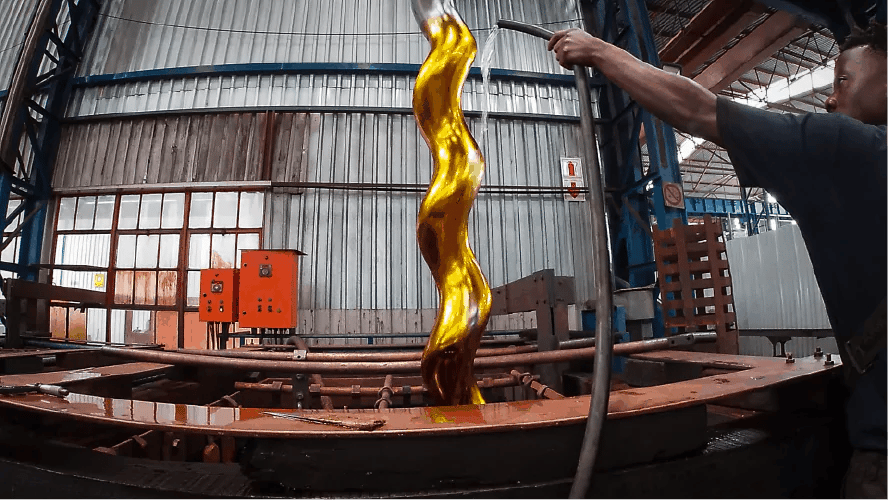

A pellet dye consists of a hollow cylindrical body capped at one end, forming a blind tube into which a powder sample pours. Jünger refurbishes the dies to create thin cylindrical pellets from a powder using a pellet press.

Ring dies for pellet presses do not need to be replaced when they eventually wear out. When presses become worn out or clogged, Honingcraft can refurbish them. Refurbishing extends the life of your die, restoring capacity and improving your product quality.

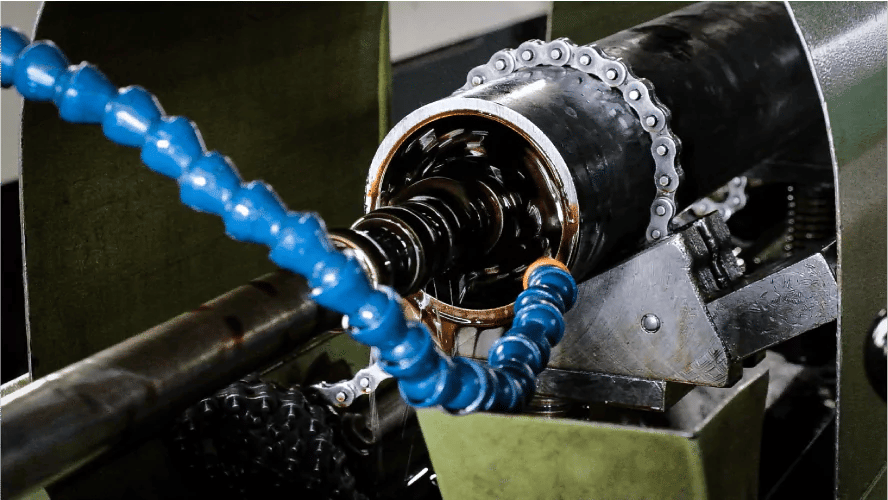

The roller and die are the wear parts of a pellet machine. Using and maintaining them in the right way will reduce the failure rate, increase the quality, increase the manufacturing rate, save time and labour.

The refurbishing process allows you to maintain die integrity for optimum pelleting efficiency. It also aids in reducing the energy consumption of the pellet press, and lastly, Honingcraft assures quality refurbishing – every time.

Reach out to us for your pellet dye refurbishing needs. See what other general engineering services we can assist you.