Honingcraft Moser and Honingcraft Jünger can chrome shafts with a maximum diameter of 1,000 mm, at lengths up to 10,000 mm. Our rectifiers can supply 124,000 amps of power into 122 kilolitre baths of chromic acid baths supported by 100 tonnes of combined overhead cranage. Our 500 years of combined chroming experience makes us the most knowledgeable chroming team in the African industry.

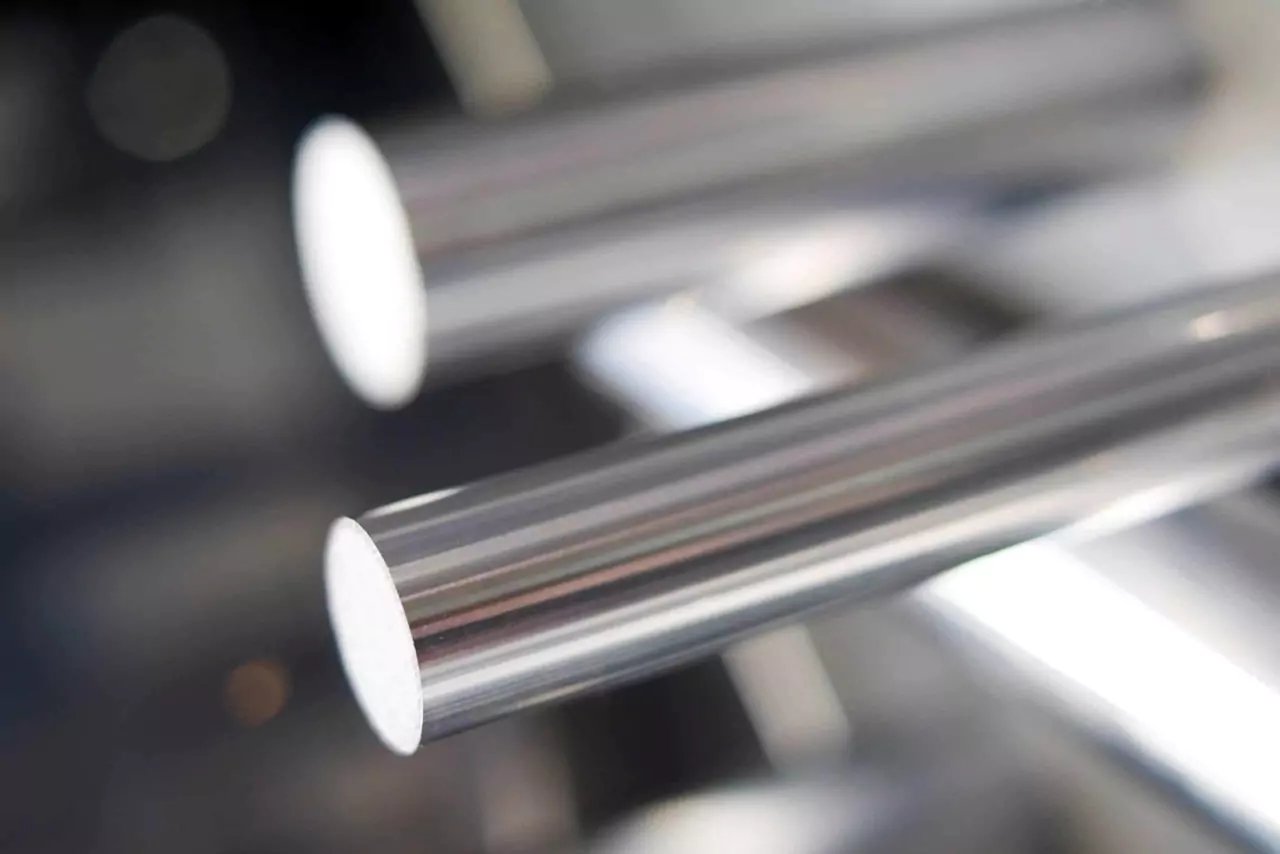

Chrome plating, often called chroming, is a technique of electroplating a thin layer of chromium onto a metal object. Industrial chroming, or Hard Chrome, extends the life of any treated product by providing corrosion resistance, increasing surface hardness and easing cleaning procedures. The chrome layer provides corrosion resistance, reduces seal operations and increases surface hardness. We offer a fast turnaround with no compromise on client specifications, no deviation from tube size or agreed deadline.

Honingcraft also offers re-chroming services. Rechroming is an excellent solution for restoring cylinder rods, pellet dies and rollers. The entire process of re-chroming, from stripping old chromium plating to grinding damaged base materials and re-chroming, is done at Honingcraft Jünger.

Getting started with a chroming job is easy at Honingcraft. Customers who require the service will first reach out to us via our website or give our sales team a call. Our sales team has expert knowledge and understands most of the required applications to get a chrome bar.

We chrome cylinder rods to prevent corrosion and to make the seals “glide” over the surface more easily. Honingcraft chromes tubes on the inside and outside in the case of manufacturing telescopic cylinders because you also want the different stages to “glide” smoothly.

Honingcraft will inspect your tube or cylinder rods to see what needs to be completed for your chroming to be successful. If your bar is damaged, HOningcraft will pay special attention to the areas that need to be fixed.

This is where your product will go to the stripping bath. Products are placed in the stripping bath for a few hours. After this, your honed tube or cylinder rods are removed, scrubbed, and rinsed in clean water.

Old chrome is removed in a caustic bath. Here it is electrified to 12V with a reverse charge. Old chrome can be removed in about 10 minutes. Chrome plating applies a positive current to a chrome solution, and reverse electrolysis does the opposite.

Grinding can also remove old chrome with large stone grinding wheels. The rod is centred on a large lathe-like grinding machine. The rod is rotated constantly and brought into contact with the spinning stone grinding wheel.

Parts must be cleaned before plating. This is done by using a series of soap, acid, and water solutions. The rod is then cleaned, and the ends are masked.

This process involves placing objects to be plated in a bath containing a solution of dissolved metal molecules. Electrodes are attached to the object, and a positive current is applied to the solution. This causes the dissolved metal particles in the solution to be attracted to and adhere to the metal surface of the object.

The rods are finished in two stages: post-grinding and linishing. The chrome coating is reduced to the required thickness in each stage and polished for a perfect surface finish.

A Honingcraft inspector will inspect the optimal surface thickness, optimal roughness, no cracking of chrome and no excessive pitting or pinholes.

Once your rods are ready, a Honingcraft professional will wrap and package your stock for delivery or collection. The completed rod is wrapped in cardboard and protective plastic. Read more about handling chrome stock.

Hard chrome’s practical wear and anti-corrosion advantages make it a popular application for hydraulic cylinders, but there are even more advantages.

Chrome plating, often called chroming, is a technique of electroplating a thin layer of chromium onto a metal object. Industrial chroming, or Hard Chrome, extends the life of any treated product by providing corrosion resistance, increasing surface hardness and easing cleaning procedures.

The chrome layer provides corrosion resistance, eases seal operations and increases surface hardness. We offer a fast turnaround with no compromise on client specifications, no deviation from tube size or agreed deadline.

According to the dynamic characteristics of the electrochemical system, and according to researcher V.F. Molchanov, it is possible to “optimise the composition of the chroming electrolytes and predict the properties of chromium deposits depending on the mode of deposition and the transition time. The possibility of using the transition time for forming the cathode surface colloid-dispersion film to study the chemical composition of the chroming solution is considered”.

“The chemical composition can be optimised by the position of the maxima and minima on the polarisation curves. An electrochemical cell can be described as a system by a differential equation, the form of which is determined by its internal structure, which varies with electrolysis conditions. The properties of the system are evaluated by several factors: the time of the transition process, forcing, attenuation, and the quality factor”, Molchanov concludes.

Copyright © Honingcraft 2025 – All Rights Reserved | Privacy Policy | Site by Xponent