By reconditioning engine liners used for diesel engines for both ships and locomotives, the productive lifespan of these critical components can easily be doubled at a fraction of the cost of a replacement.

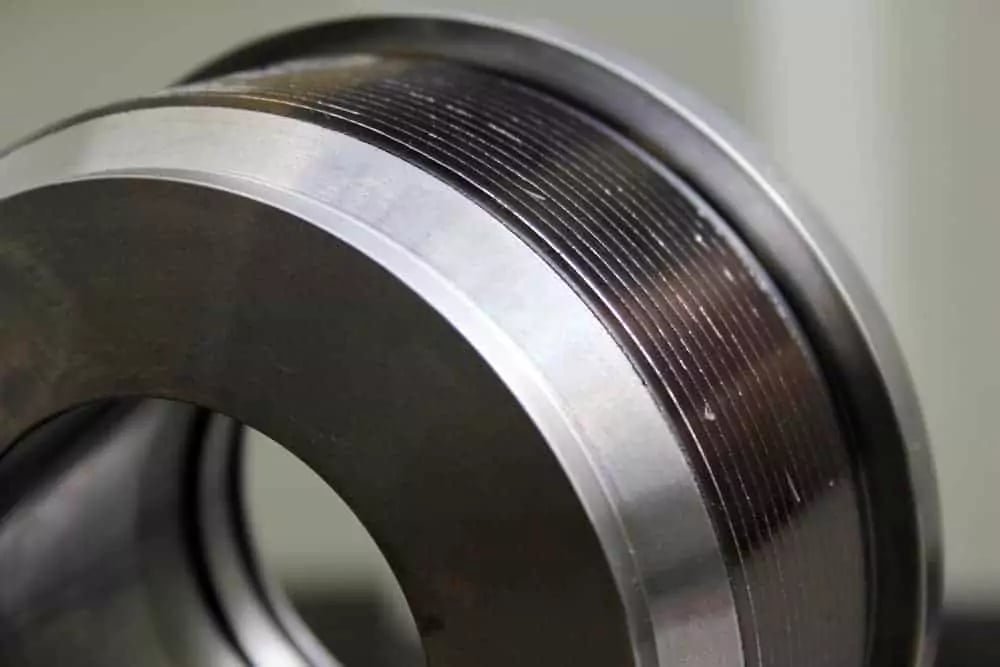

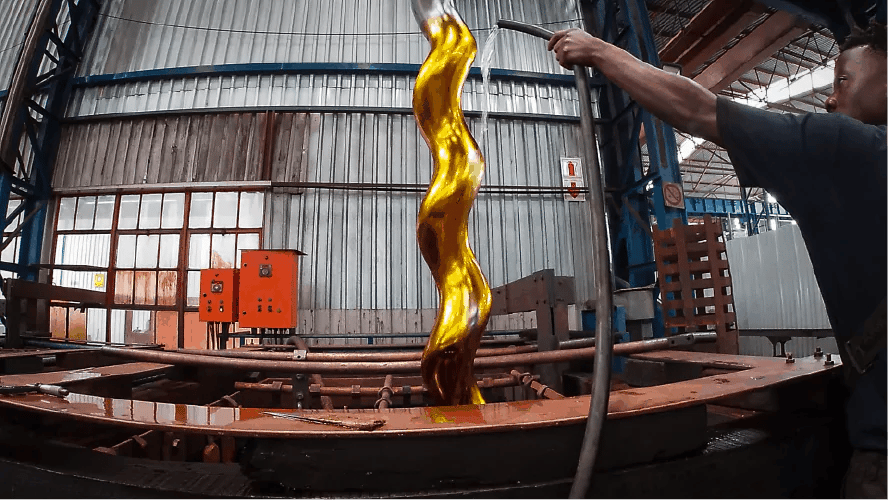

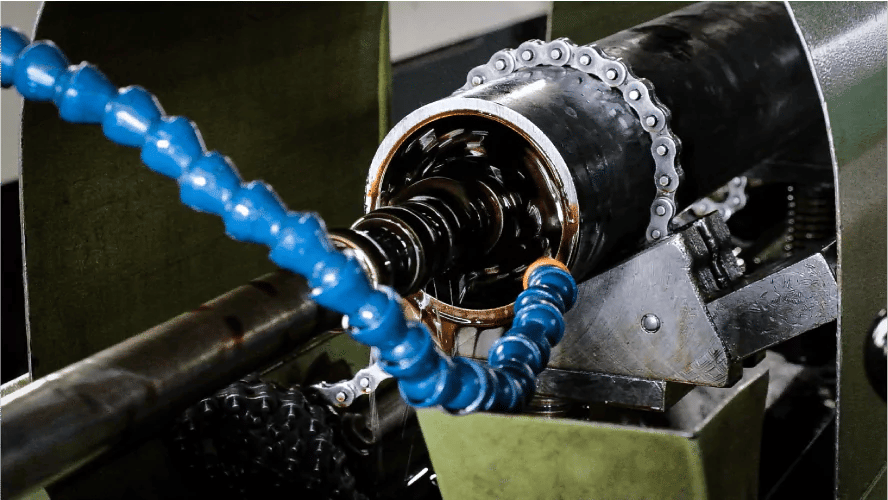

Using Moser Hardchrome, we are able to repair damage to the inside bore leaving the engine liner with a finish which is superior to the brand new component. Diesel engines used in railroad locomotives and for ships engines contain liners inside their cylinders. The intricate design of these liners results in a high replacement cost making it more cost effective to recondition the liner, than substituting it with a new one.

By reconditioning ship and locomotive engine liners, the productive lifespan can easily be doubled. Honingcraft Moser operates plant and machinery built specifically for this purpose, which guarantees a perfect finish for each of the liners our clients send.

Increase your profitably by extending the life of your liners with our reconditioning services. The combination of experienced re-conditioners and high-quality machines, ensure that our clients receive the best reconditioned diesel engine liners at an affordable price.

Engine liner reconditioning is available at Honingcraft Moser in Germiston.