Imagine a world where your hydraulic cylinders never leaked. No more messy puddles, no more wasted fluid, and most importantly, no more unexpected downtime costing your business valuable time and money. For manufacturers striving for peak efficiency and reliability, achieving zero-leakage demands in hydraulic cylinders isn’t just a dream; it’s a critical objective.

As a hydraulic cylinder manufacturer, you understand the intricate dance between precision engineering and robust performance. Leaks, even minor ones, compromise this balance, leading to reduced efficiency, environmental concerns, and potential safety hazards. So, how do you move beyond simply minimising leaks to truly conquering them?

The answer lies not in a single magic bullet but in a holistic approach that focuses on the fundamental components and their interactions, particularly the cylinder rod and its surrounding environment.

The Foundation of Zero-Leakage Hydraulics: Cylinder Rod Excellence

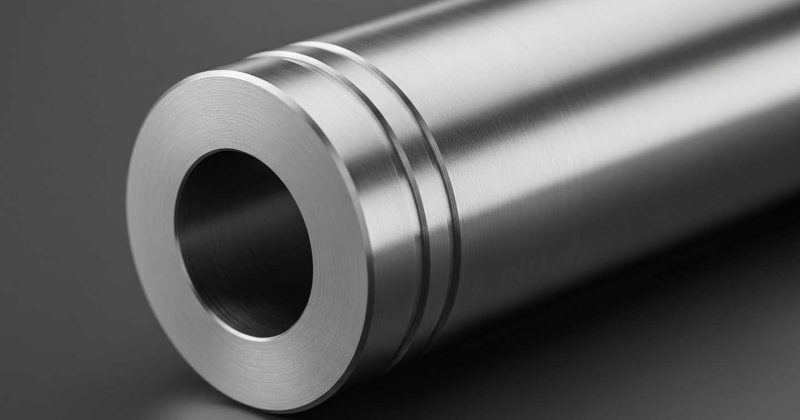

At the heart of every high-performing hydraulic cylinder is a meticulously crafted cylinder rod. Its surface finish, material composition, and treatment play a pivotal role in preventing leaks. Think of the cylinder rod as the central artery of your hydraulic system; any imperfection can lead to a compromise in its function.

Surface Finish: More Than Just Aesthetics

A smooth, consistent surface finish on the cylinder rod is paramount. Microscopic imperfections, even those invisible to the naked eye, can create pathways for hydraulic fluid to escape past seals. Honing, a precise abrasive machining process, is crucial here. It creates a cross-hatch pattern on the rod’s surface that not only reduces friction but also helps retain a thin film of oil, acting as an additional barrier against leakage.

Material Selection: The Unsung Hero

The material of your cylinder rod directly impacts its resistance to wear, corrosion, and deformation. Common choices include chrome-plated steel, induction hardened chrome-plated steel, and stainless steel, each offering distinct advantages depending on the application’s demands. For instance, in corrosive environments, stainless steel or specific corrosion-resistant coatings become non-negotiable.

Treatment: Enhancing Durability and Performance

Beyond the base material, various treatments can significantly enhance the cylinder rod’s properties. Hard chrome plating is a widely used and effective method, providing exceptional hardness, wear resistance, and corrosion protection. However, other advanced treatments like nitriding or laser cladding are gaining traction for their ability to deliver superior performance in demanding applications. These treatments alter the surface properties of the rod, making it more resilient and less prone to leakage-inducing wear.

The Role of Superior Sealing Solutions

Even with the most perfectly manufactured cylinder rod, the seals are the final line of defence against leakage. Choosing the right seals and ensuring their proper installation are non-negotiable for achieving zero-leakage demands.

Seal Type | Common Material | Advantages | Disadvantages | Ideal Applications |

Piston Seals | Nitrile Rubber (NBR), Polyurethane (PU) | Good all-around performance, wide temperature range | Can wear over time, susceptible to certain chemicals | General industrial hydraulics |

Rod Seals | Polyurethane (PU), PTFE | Excellent wear resistance, low friction | Can be sensitive to pressure spikes | Heavy-duty industrial and mobile hydraulics |

Wiper Seals | Polyurethane (PU), NBR | Prevents contaminants from entering the cylinder | Not designed for pressure sealing | All hydraulic cylinder applications |

Static Seals (O-rings) | NBR, FKM (Viton) | Simple, cost-effective, good for static sealing | Not for dynamic applications | Flanges, end caps |

Selecting the appropriate seal material and design for your specific operating conditions is critical. Factors such as pressure, temperature, fluid compatibility, and the presence of abrasive contaminants all influence seal performance and longevity. Investing in high-quality seals from reputable suppliers pays dividends in the long run by significantly reducing the risk of premature failure and subsequent leakage.

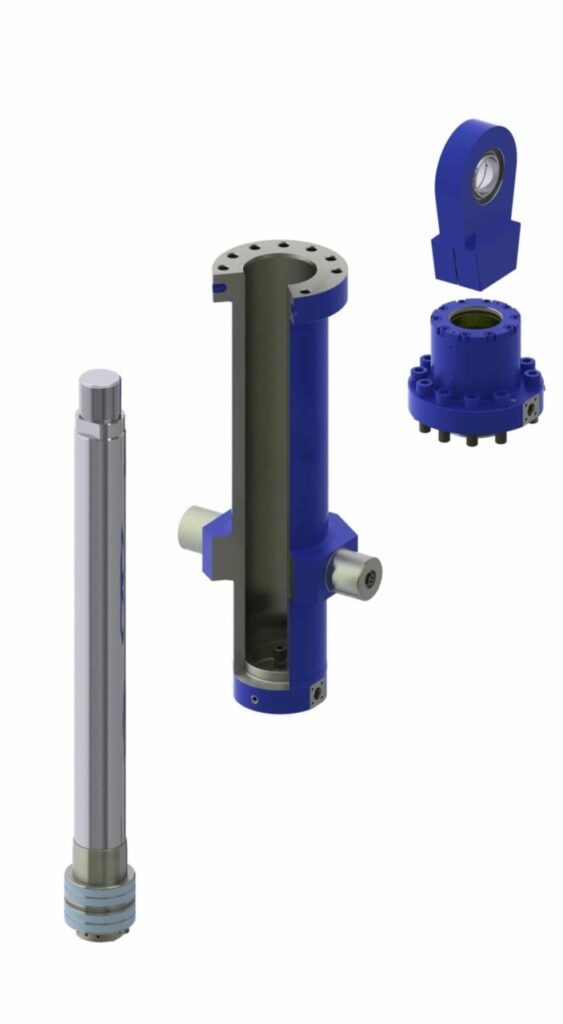

Precision Engineering and Assembly: The Missing Link

Even with the best components, a hydraulic cylinder will fail to meet zero-leakage demands if it’s not assembled with absolute precision. Tolerances, concentricity, and alignment are crucial. Misalignment during assembly can lead to uneven wear on seals and rod surfaces, creating pathways for fluid escape.

- Tight Tolerances: Maintaining incredibly tight tolerances during machining ensures that all components fit together seamlessly, minimising gaps and potential leak points.

- Concentricity and Alignment: The piston rod must be perfectly concentric with the cylinder bore. Any deviation can cause uneven loading on seals and premature wear.

- Contamination Control: During assembly, even microscopic dust particles can compromise seal integrity. A clean room environment and meticulous handling practices are essential.

This is where the expertise of a dedicated hydraulic component manufacturer truly shines. At Honingcraft, we understand that every step in the manufacturing process contributes to the overall integrity of the final product. Our commitment to precision engineering ensures that our components are ready to meet the most stringent zero-leakage hydraulics requirements.

Proactive Maintenance and Monitoring

While the focus on initial design and manufacturing is paramount, ongoing maintenance also plays a crucial role in preventing leaks and extending the life of your hydraulic cylinders.

- Regular Inspections: Periodically inspecting cylinders for visible signs of wear, damage, or minor weeping can help identify potential issues before they escalate into major leaks.

- Fluid Analysis: Regularly analysing hydraulic fluid for contaminants, water ingress, or degradation can provide early warnings of potential problems that could lead to seal failure.

- Seal Replacement Schedules: Implementing a preventative seal replacement schedule, based on operating hours or environmental factors, can significantly reduce the likelihood of unexpected leaks.

By combining superior component quality with rigorous assembly and a proactive maintenance strategy, manufacturers can confidently aim for and achieve zero-leakage demands in their hydraulic systems.

Your Partner in Achieving Zero-Leakage Demands

At Honingcraft, we are committed to providing the highest quality cylinder rods and hydraulic components that form the bedrock of leak-free hydraulic systems. Our expertise in precision honing, material selection, and advanced surface treatments empowers hydraulic cylinder manufacturers to build cylinders that consistently meet and exceed performance expectations.

Ready to elevate your hydraulic cylinder performance and virtually eliminate leakage? Explore Honingcraft’s range of high-precision cylinder rods and discover how our commitment to quality can help you achieve your zero-leakage demands. Visit our product pages to learn more about our materials and capabilities, or contact us directly to discuss your specific requirements.