Welding

During the course of most precision steel manufacturing projects, welding is often needed for a large variety of reasons.

During the course of most precision steel manufacturing projects, welding is often needed for a large variety of reasons.

Honingcraft ensures quality through traceability. All the products on our workshop floor are marked with unique identifying job number codes. Identification and traceability are requirements of the ISO 9001 Standards.

Honingcraft delivers outstanding service to our customers. We offer free delivery within 25 km radius of our workshop locations.

Honingcraft offers cardboard covering or custom built crates, and will tack weld cover plates onto barrels to prevent damage during loading.

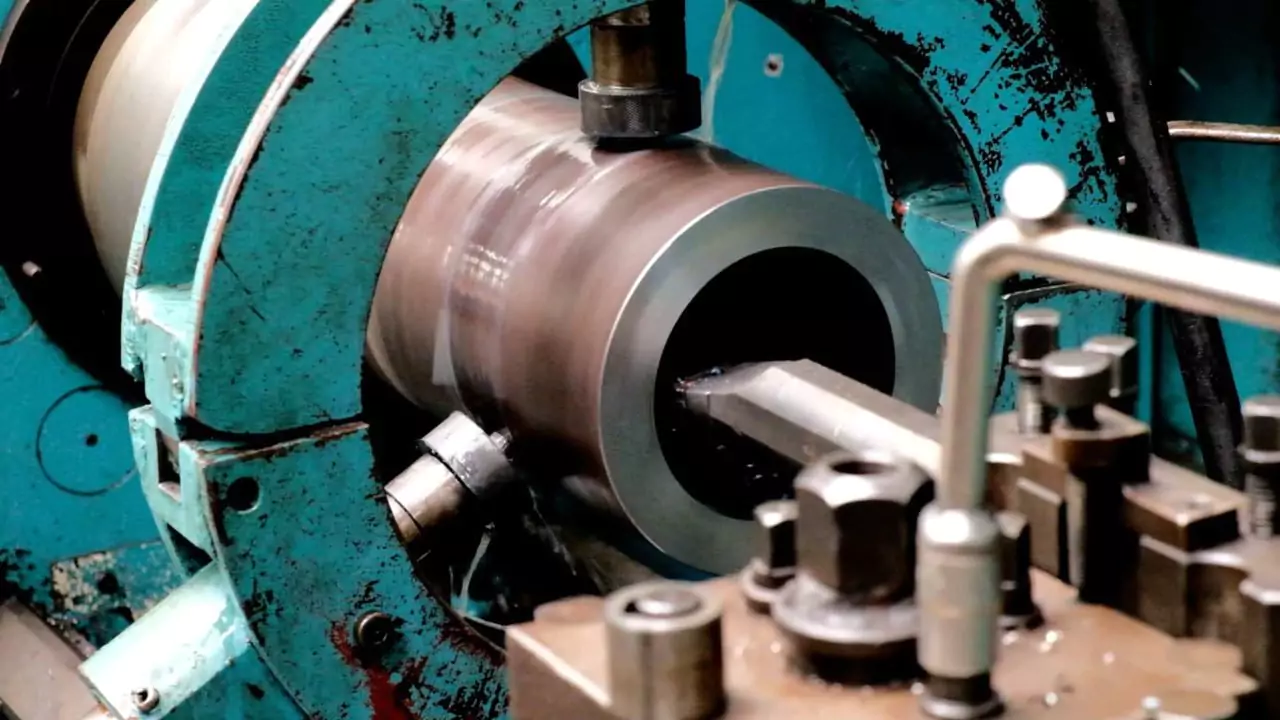

Recondition rock drill sleeves, hydraulic cylinder barrels and rods, engine liners and pump shafts.

We electroplate inside diameters, outside diameters and flat surfaces with bronze to ensure surfaces are wear resistant.

Honingcraft Moser operates one of the largest shaft chroming plants in Africa, enabling us to provide any industrial chroming requirement.

Our experienced artisans operate the world’s most sophisticated grinding machines to precision tolerances.

Honingcraft manufactures custom tubes to your specification with our state of the art boring machines. We specialise in boring hollow bar for use in the manufacture of hydraulic cylinders.

We are superbly armed to hone with high precision, package with diligence, and deliver without time waste.

Copyright © Honingcraft 2025 – All Rights Reserved | Privacy Policy | Site by Xponent