Choosing the Correct Material and Treatment for Your Cylinder Rods

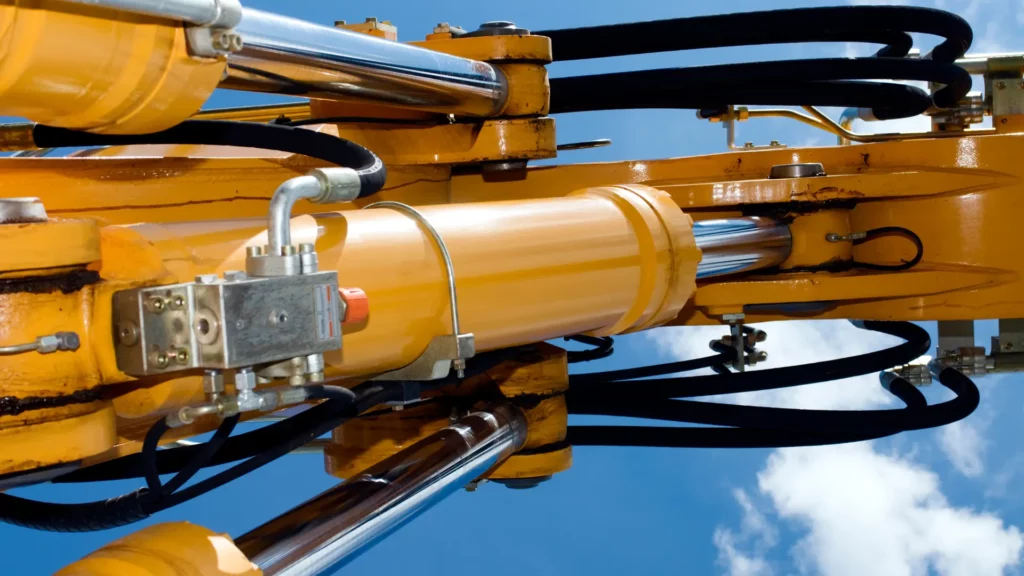

Hydraulic cylinder rods are the workhorses of many machines, guiding pistons and transferring force within a hydraulic or pneumatic system.

Why Hydraulic Cylinders Fail: Maintaining Synchronisation and Hydraulic Harmony

Hydraulic cylinders are the undisputed champions among industrial giants.

Why Hydraulic Cylinders Fail: Using Incorrect or Cheap Hydraulic Oil

Hydraulic cylinders are susceptible to failure, and one of the leading culprits is the improper use of hydraulic oil.

5 Causes of Hydraulic Cylinder Failure: Under-design, Understated Seals, Overpowered Fluid Application, and Injection

In this article, we’ll explore four critical factors that often lead to failure: under-design of cylinders, understated seals, overpowered fluid application, and injection.

How Uneven Load Distribution Causes Hydraulic Cylinder Failures

In this article, we will explore why uneven loads lead to hydraulic cylinder failure and how to prevent such issues.

Why Hydraulic Cylinders Fail: The Impact of Misalignment and Side Thrust

One of the common causes of hydraulic cylinder failure is misalignment, particularly in the clevis and side thrust areas.

The Role of Hydraulic Pump Leaks in Hydraulic Cylinder Failure

Hydraulic pump leaks not only result in fluid loss but also compromise the system’s ability to maintain optimal operating temperatures.

Why Hydraulic Cylinders Fail: Understanding Hydraulic Oil Contamination

Hydraulic oil Contamination in your hydraulic system, often in the form of microscopic particles of dirt, debris, or even water, can have a devastating impact on your cylinders.

The High Cost of Hydraulic Cylinder Failures: Understanding the Implications

Hydraulic cylinders are not immune to failure. When a hydraulic cylinder fails, the consequences can be severe, impacting productivity, safety, and the bottom line.

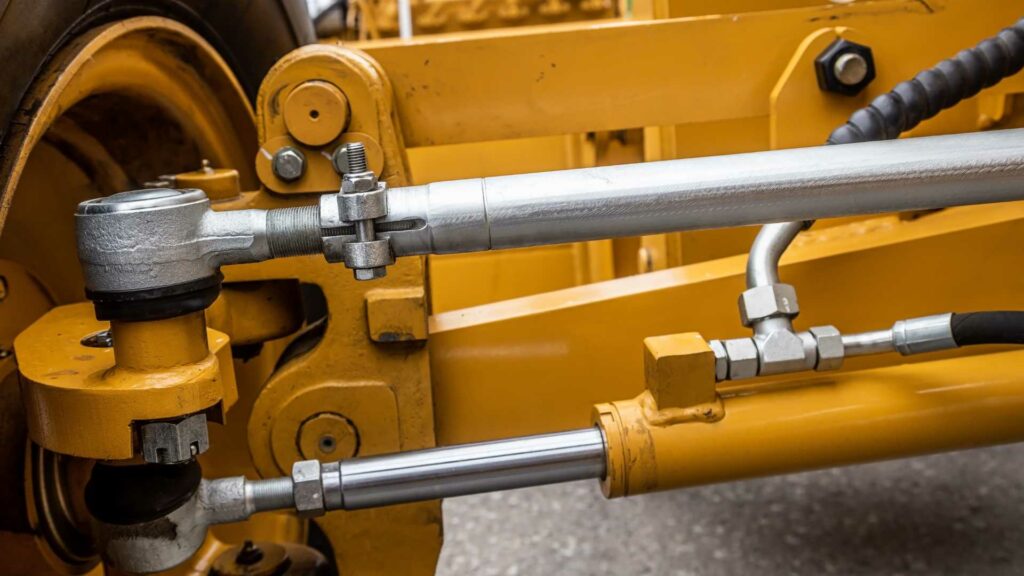

How to Choose the Right Fittings for Your Hydraulic Cylinders

Unlock the secrets of applying the perfect hydraulic fittings.