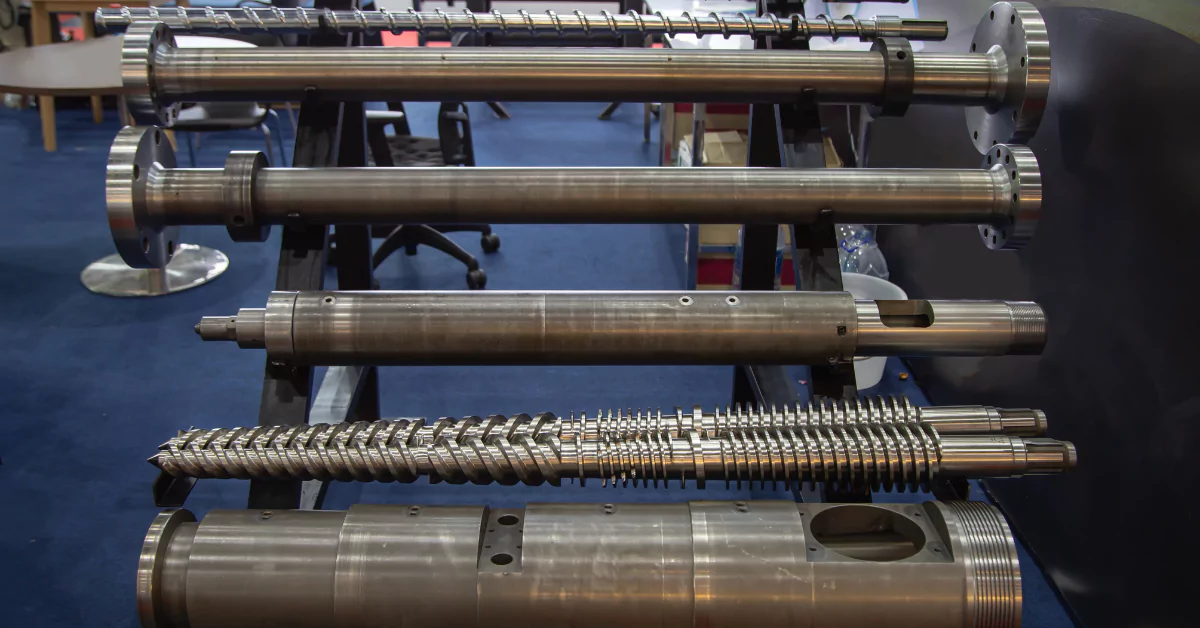

Extrusion Barrel Reconditioning

Welding cylinder tubes often result in distortion of the material and we offer a hone after-weld service, at no extra cost, where our customers are supplied with honed or unhoned material, and after machining and welding the material, it is returned to Honingcraft for the final honing process. This ensures the best possible tolerances on welded cylinders.