At Honingcraft, we know that precision and reliability are everything in the world of hydraulic cylinder manufacturing. Adhering to industry standards isn’t just about ticking a box; it’s about building a reputation for excellence. For professionals in hydraulics, aerospace, oil and gas, and construction, understanding and leveraging ISO Standards is a powerful way to ensure quality and gain a competitive edge. We want to guide you through the most critical ISO standards for hydraulic cylinder manufacturing and show you how to use them to your advantage.

What Are ISO Standards and Why Do They Matter to Us?

The International Organisation for Standardisation (ISO) develops and publishes standards that provide a consistent framework for products and services globally. When we manufacture a hydraulic cylinder, or a component of it, to an ISO standard, we’re meeting a specific, internationally recognised benchmark for quality, safety, and performance.

For you, our customer, this means a few things:

- Trust and Reliability: It gives you confidence that the products you source from us are dependable and will perform exactly as expected.

- Global Compatibility: It ensures our components are compatible with systems worldwide, which opens up new markets and opportunities for you.

- Risk Reduction: It significantly reduces the likelihood of product failures, costly recalls, and warranty claims.

Simply put, using ISO standards helps us speak a universal language of quality with you, our partners.

Key ISO Standards in Hydraulic Cylinder Manufacturing

While there are many ISO standards, a few are particularly relevant to the components we manufacture. Let’s look at some of the most important ones.

ISO 10762: Mounting Dimensions and Rod End Connections

This standard is fundamental as it defines the mounting dimensions and rod end connections for single-rod hydraulic cylinders. It ensures that a cylinder manufactured by us can be easily interchanged with a cylinder from another company, as long as both comply with ISO 10762. This standard covers bore diameters from 25 mm to 500 mm.

ISO 3320: Piston Rod and Piston Diameters

This standard specifies the preferred diameters for piston rods and pistons. By following this, we ensure that our components fit a wide range of standard cylinders, making it easier for you to select replacement parts or design new systems.

ISO 4393: Cylinder Bore and Piston Diameters

Similar to ISO 3320, this standard focuses on the diameters of the cylinder bore and piston. Our compliance here ensures a proper fit and optimal performance, minimising leaks and extending the life of the cylinder.

ISO 6149: Connections for Fluid Power and General Use

This standard specifies the dimensions, design, and performance requirements for ports and stud ends for use in hydraulic and pneumatic systems. It is crucial for ensuring leak-free connections, which is a major concern in high-pressure applications.

How We Use ISO Standards to Your Advantage

Knowing about these standards is one thing; leveraging them to build a better business for you is another. Here’s how we do it:

- We Educate Our Clients: We use our website and marketing to explain how our adherence to ISO standards translates to tangible benefits for you, our customers, such as greater reliability and longer product life.

- We Showcase Quality: We are always happy to highlight which ISO standards our products meet, as this acts as a third-party endorsement of our quality.

- We Lead with Knowledge: By being experts on these standards, we can better advise you on the right components for your specific applications, building a reputation as your trusted authority.

This table provides a quick reference for some of the critical ISO standards and their relevance to the components we supply.

ISO Standard | Description | Relevance to Hydraulic Cylinder Manufacturing |

ISO 10762 | Mounting dimensions, rod end connections | Ensures interchangeability and standardisation |

ISO 3320 | Piston rod and piston diameters | Facilitates component selection and repair |

ISO 4393 | Cylinder bore and piston diameters | Guarantees proper fit, reduces leakage risk |

ISO 6149 | Connections for fluid power | Critical for leak-free, high-pressure systems |

By adhering to these standards, we are not just meeting a requirement, but we’re also providing you with a better product and a better service.

Beyond the Standards: Our Commitment to Quality

While ISO standards provide a solid foundation, true quality goes beyond just the specifications. It’s about the materials we use, the precision of our machining, and the quality control throughout the entire hydraulic cylinder manufacturing process.

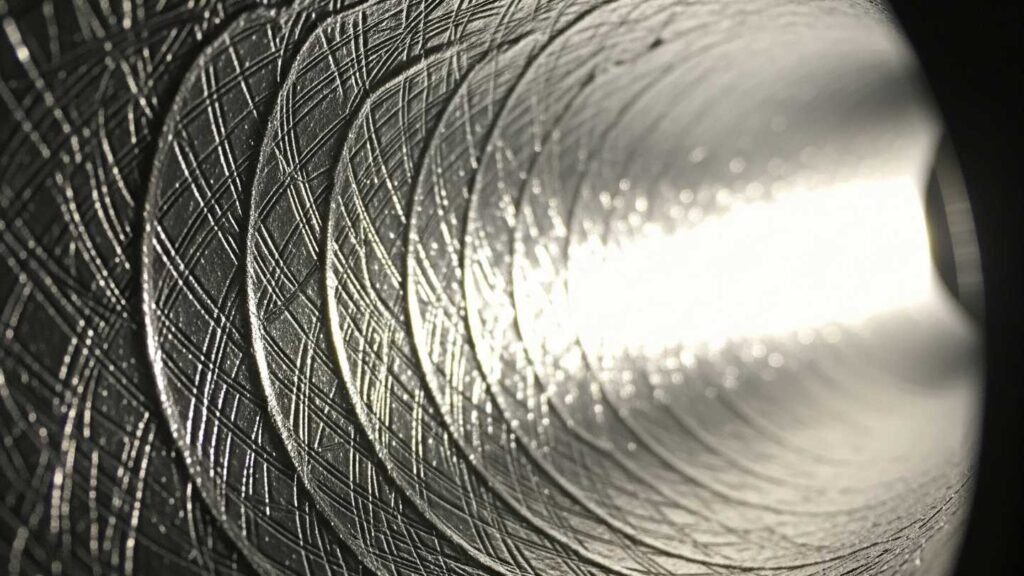

For example, the chrome bars we supply for hydraulic rods must be of the highest quality to withstand wear and corrosion. Similarly, our honing process for cylinder tubes is a critical step that ensures a perfect surface finish for optimal seal performance.

When you partner with us, you can trust in our entire process, from material sourcing to quality assurance. Honingcraft is a company that focuses on providing high-quality, cold-drawn seamless tubing and CK45 chrome bars, which are essential for manufacturing durable cylinders. Our commitment to these standards and processes is what sets us apart. You can explore our full range of products on our Honingcraft Products page.

A Final Word on Strategic Sourcing

For professionals in this field, making the right decisions about where to source components can directly impact the success of a project. Using a trusted supplier that understands and applies ISO standards consistently is a strategic move. It saves you time, reduces risk, and ensures you’re always delivering a top-tier product. We believe we are that supplier, providing not only the raw materials but also the finished components, from honed tubes to chrome bars, that meet the highest quality benchmarks.

Your Next Step in Quality Assurance

Understanding and applying ISO standards is a critical step towards producing superior hydraulic cylinders. But true success comes from partnering with a company that shares your commitment to quality and precision.

Are you looking to ensure your hydraulic cylinders are built to the highest international standards? Honingcraft provides a comprehensive range of components, from honed tubing to chrome bars, all manufactured with precision and a deep understanding of industry requirements.

Ready to elevate your projects? Contact Honingcraft today to learn more about our offerings and how we can support your hydraulic cylinder manufacturing needs.