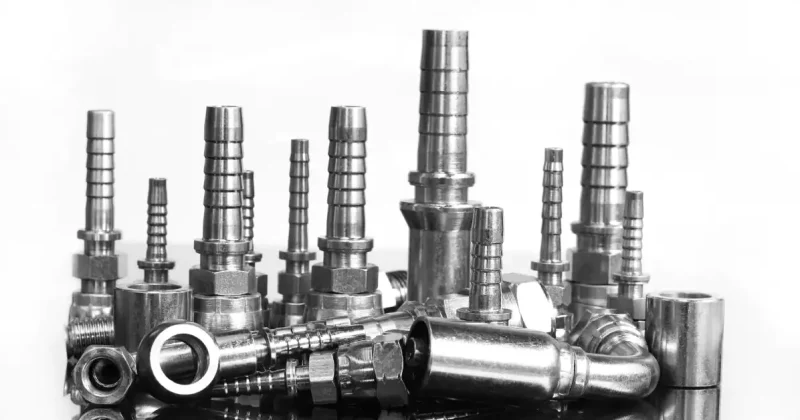

In the heart of countless industrial machines, hydraulic cylinders translate fluid power into precise linear motion. But these workhorses rely on unsung heroes: the fittings that connect them to the rest of the hydraulic system. Choosing the right fittings isn’t just about making things fit; it’s about ensuring efficiency, safety, and longevity for your entire operation.

Here at Honingcraft, we understand the critical role fittings play in hydraulic systems. So, let’s delve into the key factors to consider when selecting the perfect fit for your cylinders:

1. Know Your System:

- Pressure: What’s the maximum operating pressure in your system? Choose fittings exceeding this rating to avoid leaks or failures.

- Fluid: Is it mineral oil, fire-resistant fluid, or something else? Ensure compatibility between fluid and fitting materials.

- Temperature: Operating and ambient temperatures matter. Opt for fittings rated for your specific range to prevent thermal degradation.

2. Size Matters:

- Port size: Match the fitting’s size to the cylinder’s port to ensure proper flow and avoid pressure drops.

- Hose or tube size: Select fittings compatible with the chosen hose or tube diameter for seamless connections.

3. Connection Type:

- Threaded: Common choices include NPT, SAE, and BSP. Ensure thread type and size match the cylinder port.

- Flanged: Offer high pressure capacity and rigidity. Consider space constraints and alignment challenges.

- Welded: Permanent, leak-proof solution for high-pressure applications. Requires specialised equipment and expertise.

4. Material Matters:

- Steel: Durable and widely available, but susceptible to corrosion in some environments.

- Stainless steel: Corrosion-resistant for harsh environments, but more expensive.

- Brass: Good for moderate pressures and non-corrosive fluids.

- Other materials: Consider specialty options like aluminium or plastic for specific needs.

5. Beyond the Basics:

- Reusability: Choose reusable fittings for easy maintenance and flexibility, or permanent options for high-pressure or tamper-proof applications.

- Vibration: If your system experiences vibrations, select fittings with features like lock nuts or crimp rings to prevent loosening.

- Ease of installation: Consider assembly methods and accessibility when choosing fittings, especially in tight spaces.

Remember: Consulting a hydraulics expert like Honingcraft can be invaluable. We can help you navigate the vast array of options, ensuring you choose the perfect fittings for your specific application, optimising performance and safeguarding your investment.

Honingcraft - Your Partners in Hydraulic Excellence

At Honingcraft, we’re more than just suppliers; we’re your trusted partners in the world of hydraulics. With our extensive knowledge and commitment to quality, we’ll help you choose the right fittings to keep your cylinders operating smoothly and efficiently for years to come. Contact us today to discuss your specific needs and experience the Honingcraft difference!