Extending the Life of Hydraulic Components

In high-stakes industries like construction, aerospace, and oil and gas, the integrity of your hydraulic and pneumatic systems is non-negotiable. The cylinder rod, often the most exposed component, must resist a relentless barrage of friction, wear, and, crucially, corrosion. A failing rod means system downtime, costly repairs, and potential safety risks. This is why material selection and surface treatment are vital.

We know professionals like you seek the most reliable and cost-effective solutions. The fundamental question is: How long can your components truly last under extreme conditions? This article reveals the compelling results of Honingcraft’s intensive salt spray corrosion test, pitting our industry-leading Chrome Bar against an innovative solution: the combination of chroming with new Laser Cladding technology. These results not only highlight exceptional performance but also mark an exciting expansion of Honingcraft’s service offerings.

Why Surface Resilience Matters in Cylinder Rods

The role of a cylinder rod’s surface treatment is twofold: it provides a low-friction surface for smooth operation and creates an impervious barrier against environmental threats. Two of the most effective methods for achieving this resilience are traditional chroming and the advanced technique of laser cladding.

The Reliability of Honingcraft's Chrome Bar

Honingcraft’s Chrome Bar is a benchmark product in the industry, characterised by a precise, extremely smooth surface finish. This finish is critical for reducing seal wear and ensuring minimal friction. Beyond the aesthetic and functional surface, the material is typically supported by an induction-hardened case, providing superior mechanical strength and resistance to accidental damage, all while maintaining good core strength for high-load applications. This combination makes chroming the industry standard for superior wear and corrosion resistance in most environments.

The Next Evolution: Understanding Laser Cladding

Laser Cladding is an advanced surface modification process that uses a high-energy laser beam to melt and fuse a layer of cladding material (often a specialised metal alloy) onto the surface of a base material. This creates a metallurgical bond, forming an exceptionally dense, low-porosity, and wear-resistant layer.

In the context of cylinder rods, a laser-clad layer provides an extra dimension of protection, acting as a tougher, more durable foundation beneath the chrome layer, or as an alternative in extremely aggressive environments. It offers unmatched protection against impact, abrasive wear, and deep corrosion penetration. Honingcraft is proud to announce that we now offer Laser Cladding as a dedicated service, bringing this cutting-edge protective technology directly to our clients.

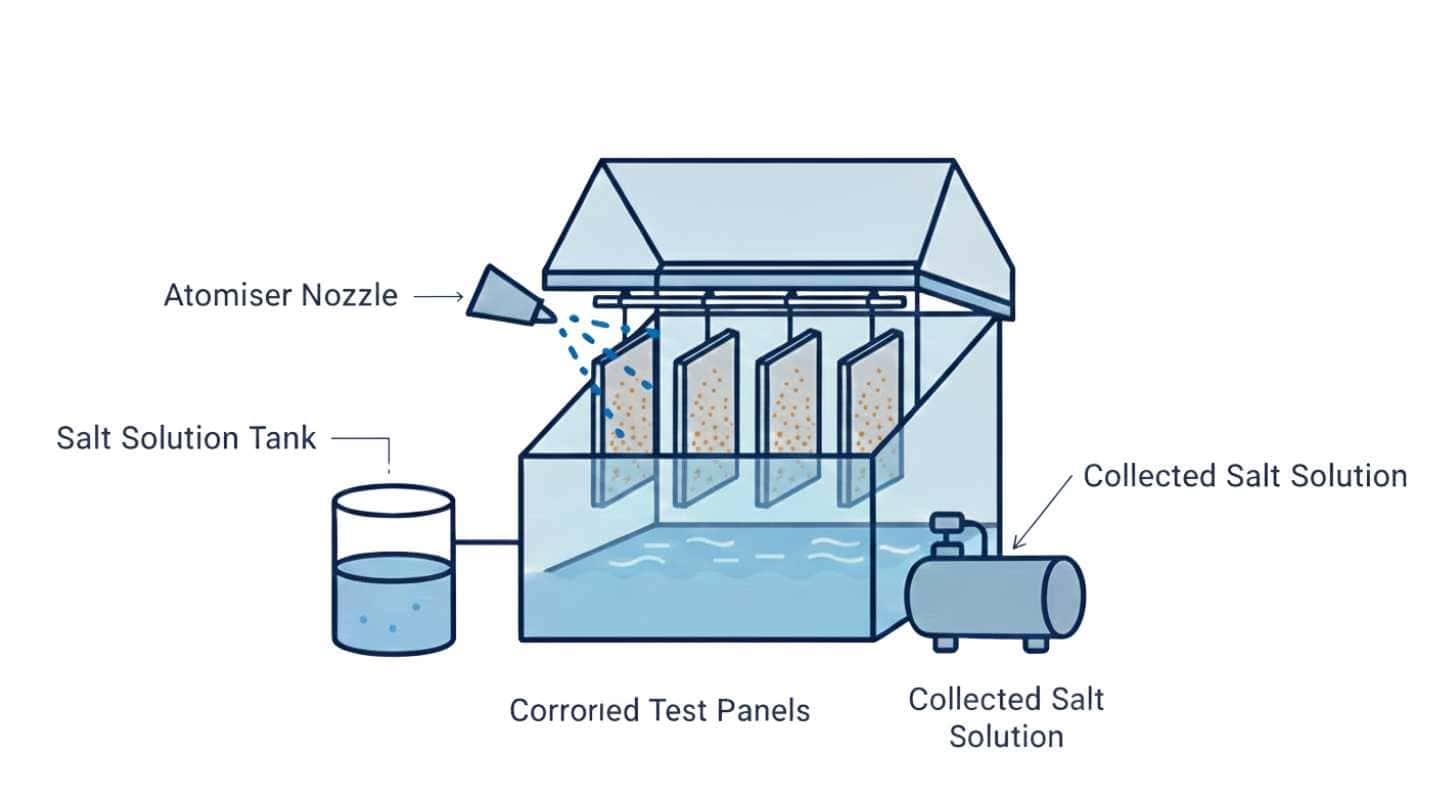

Proving Durability: The Salt Spray Corrosion Test

To scientifically validate the resilience of these surface treatments, Honingcraft subjected samples of our standard Chrome Bar and a Laser Cladded product (followed by chroming) to the rigorous salt spray corrosion test (ASTM B117). This test simulates harsh, corrosive environments, the kind found on offshore platforms or in aggressive industrial settings, by exposing the samples to a dense, atomised saltwater mist for an extended period. The hours a sample survives without exhibiting wear, corrosion, or pitting is a direct measure of its long-term durability.

Exceptional Results: Standard Chrome Bar

Our standard chrome-plated bars set a remarkably high bar for performance.

Honingcraft’s Standard Chrome Plated Bars lasted over 300 hours in the salt spray chamber without any signs of wear, corrosion, or pitting.

This result is a testament to the quality and precision of the chrome plating process employed by Honingcraft, confirming its status as a robust solution for the most demanding applications.

A New Benchmark: Laser Clad & Chromed Product

The combination of the foundational strength of Laser Cladding, followed by the smooth, low-friction surface of traditional Chroming, produced an even more outstanding result.

Honingcraft’s Laser Clad and Chromed Product lasted over 400 hours in the salt spray chamber without any signs of wear, corrosion, or pitting.

This 33% increase in corrosion resistance under the most demanding test conditions clearly demonstrates the enhanced protective capabilities of the laser-clad layer. It signifies a breakthrough in component longevity, offering a new level of durability for systems operating in extremely corrosive or abrasive environments.

Comparing Performance: Chrome Bar vs. Laser Clad

The following table summarises the key findings from our corrosion test, providing a clear comparison to help guide your material selection decision.

Feature | Honingcraft Standard Chrome Bar | Honingcraft Laser Clad & Chromed Product |

Primary Protection | High-density Electroplating | Fused Laser Cladding followed by Electroplating |

Corrosion Test Result | Exceeded 300 hours | Exceeded 400 hours |

Key Advantage | Excellent surface finish, industry-standard wear resistance, and cost-effective. | Superior corrosion barrier, exceptional resistance to abrasive wear and impact damage. |

Ideal Application | General-purpose hydraulics, construction machinery, and non-extreme environments. | Marine, offshore, mining, chemically aggressive, or high-impact environments. |

For detailed specifications on our range of standard products, please visit our Catalogue page.

Your Next Step in Durability

The results of the salt spray test are clear: Honingcraft’s commitment to quality ensures our Chrome Bar continues to be a top-tier choice for reliable performance. More significantly, the exceptional 400+ hour endurance of the Laser Clad and Chromed sample validates Laser Cladding as a superior protective solution for extreme conditions.

By offering Laser Cladding as a service, Honingcraft is equipping our partners with the next generation of surface protection. Whether your project demands the proven performance of a standard Chrome Bar or the ultimate resilience of a laser-clad component, we have the technical expertise and manufacturing capability to extend the life and reduce the downtime of your critical hydraulic systems.

Ready to specify components that last?

Contact the Honingcraft technical team today to discuss how our new Laser Cladding service or our premium Chrome Bar products can significantly improve the durability and lifespan of your hydraulic cylinder rods.