In the world of metal fabrication and manufacturing, creating holes in materials is a common and critical task. While the terms boring, drilling, and deep hole drilling might sound similar to an outsider, they represent distinct processes with different applications, tools, and outcomes. For professionals in demanding industries like hydraulics, aerospace, and oil and gas, understanding these differences is crucial for ensuring precision, efficiency, and the integrity of a final product. This article breaks down these three core machining methods.

Drilling: The Foundation of Hole Making

Drilling is the most fundamental of the three processes. It’s used to create a new hole in a solid material. This is achieved by using a rotating cutting tool, typically a twist drill bit, that penetrates the material’s surface to create a cylindrical hole. Drilling is generally used for making holes that are relatively shallow and do not require extremely tight tolerances or a precise finish.

Key characteristics of drilling:

- Purpose: To create a hole in a solid surface.

- Tool: Twist drill or similar drill bits.

- Application: General-purpose hole creation, pilot holes, and holes that don’t require a high degree of precision.

- Precision: Lower than boring or deep hole drilling.

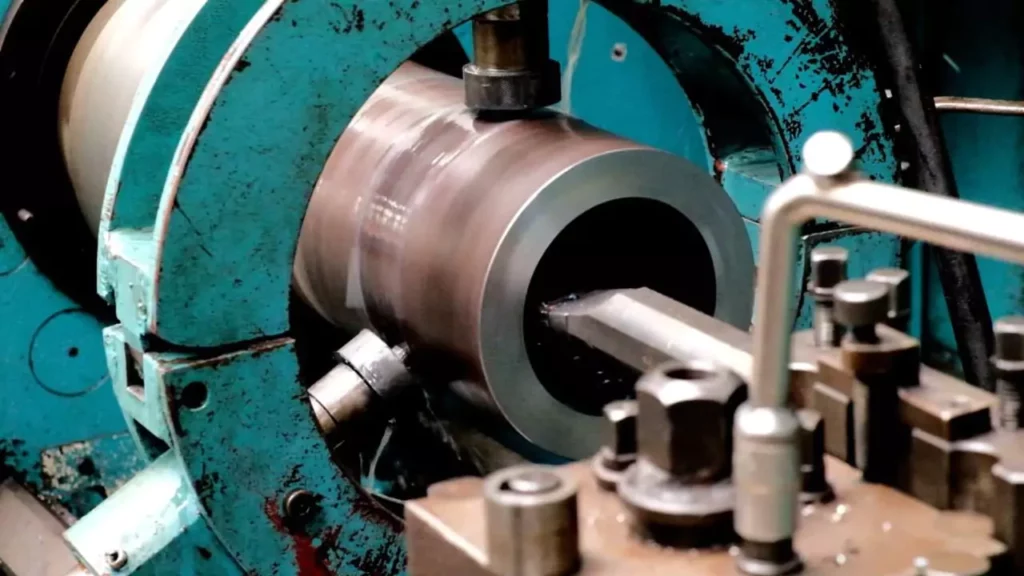

Boring: Enhancing an Existing Hole

Unlike drilling, boring is an internal machining process. It’s used to enlarge or refine an already existing hole. This can be a hole created by a previous drilling operation, or a pre-cast hole in a component. Boring is a precision process that can correct inaccuracies in the initial hole, improve its surface finish, and ensure it meets specific dimensional tolerances. The tool used, a boring bar with a single-point cutting tool, rotates inside the hole, removing material from the inner walls.

Key characteristics of boring:

- Purpose: To enlarge or refine an existing hole.

- Tool: Boring bar with a single-point cutting tool.

- Application: Finishing hydraulic cylinders, engine blocks, and other parts that require precise internal dimensions and a smooth surface finish.

- Precision: High, with excellent control over diameter and surface finish.

Deep Hole Drilling: Going Further

As the name suggests, deep hole drilling is a specialised form of drilling used to create holes with a very high depth-to-diameter ratio. While there is no universal definition, a hole is generally considered “deep” when its depth is ten times or more its diameter. This process is complex because of the challenges of chip evacuation, heat generation, and maintaining straightness over long distances. Specialised tools and machines are required to perform deep hole drilling, such as BTA (Boring and Trepanning Association) drilling and gun drilling.

Key characteristics of deep hole drilling:

- Purpose: To create holes with a high depth-to-diameter ratio.

- Tools: Gun drills or BTA tools.

- Application: Creating holes in drive shafts, oil and gas components, and aerospace parts.

- Precision: Requires advanced equipment to maintain straightness and a clean finish over long lengths.

A Comparative Look at Boring Drilling and Deep Hole Drilling

To make it easier to see the differences, here is a quick overview of how these three processes compare on key aspects.

Feature | Drilling | Boring | Deep Hole Drilling |

Starting Point | Solid material | Existing hole | Solid material or existing holes |

Primary Goal | Creating a new hole | Enlarging/refining a hole | Creating a very long, straight hole |

Depth-to-Diameter Ratio | Low | Low (internal) | High (>10:1) |

Tool Type | Twist drills, spade drills | Boring bar (single-point tool) | Gun drills, BTA tools |

Precision | General purpose | High (for diameter and finish) | High (for straightness and finish) |

Coolant/Lubrication | Often external or through-spindle | Often external | High-pressure internal delivery |

The Right Tool for the Job

Choosing between boring, drilling, and deep hole drilling depends on the specific requirements of the project. If you’re simply making a hole for a bolt to pass through, basic drilling is likely sufficient. If you need a perfectly sized and smooth cylindrical passage for a hydraulic piston, boring is the process you need. And when a component requires a long, straight channel for a fluid or electrical line, the specialised techniques of deep hole drilling are essential.

Understanding these distinctions allows you to select the correct approach from the start, saving time and money while ensuring the highest quality in your manufacturing process. For professionals, this knowledge translates directly into improved product performance and reliability.

At Honingcraft, we understand the precise demands of these machining processes. Our expertise in hydraulic cylinder manufacturing enables us to apply these techniques to achieve optimal results precisely.

Partner with Honingcraft

Whether you’re developing components for aerospace, building heavy construction machinery, or working on critical infrastructure for oil and gas, the quality of your machined parts is non-negotiable. Our team is equipped with the knowledge and technology to help you make informed decisions about your project.

To learn more about our services and how we can assist with your specific application, please visit our website. Our comprehensive offerings, including our range of honing and finishing services, can help you achieve the precision and performance you need.